NCEES - PE Civil Engineering Exam Braindumps

Killexams.com NCEES-PE Exam Braindumps contain complete question pool, updated in April 2024 including VCE exam simulator that will help you get high marks in the exam. All these NCEES-PE exam questions are verified by killexams certified professionals and backed by 100% money back guarantee.

NCEES-PE syllabus - NCEES - PE Civil Engineering Updated: 2024 | ||||||||

| Memorize these NCEES-PE dumps and register for the test | ||||||||

|

||||||||

|

||||||||

|

Exam Code: NCEES-PE NCEES - PE Civil Engineering syllabus January 2024 by Killexams.com team | ||||||||

NCEES-PE NCEES - PE Civil Engineering The Principles and Practice of Engineering (PE) exam tests for a minimum level of competency in a particular engineering discipline. It is designed for engineers who have gained a minimum of four years post-college work experience in their chosen engineering discipline. The PE Civil exam is an 8-hour exam with 80 questions. It is administered in pencil-and-paper format twice per year in April and October. See the exam schedule for specific dates. Reviewing the PE exam specifications and design standardsReading the reference materials and examinee guideUnderstanding scoring and reportingViewing the most up-to-date PE exam pass rates I. Project Planning A. Quantity take-off methods B. Cost estimating C. Project schedules D. Activity identification and sequencing II. Means and Methods A. Construction loads B. Construction methods C. Temporary structures and facilities III. Soil Mechanics A. Lateral earth pressure B. Soil consolidation C. Effective and total stresses D. Bearing capacity E. Foundation settlement F. Slope stability Civil Breadth exam Specifications Continued IV. Structural Mechanics A. Dead and live loads B. Trusses C. Bending (e.g., moments and stresses) D. Shear (e.g., forces and stresses) E. Axial (e.g., forces and stresses) F. Combined stresses G. Deflection H. Beams I. Columns J. Slabs K. Footings L. Retaining walls V. Hydraulics and Hydrology A. Open-channel flow B. Stormwater collection and drainage (e.g., culvert, stormwater inlets, gutter flow, street flow, storm sewer pipes) C. Storm characteristics (e.g., storm frequency, rainfall measurement and distribution) D. Runoff analysis (e.g., Rational and SCS/NRCS methods, hydrographic application, runoff time of concentration) E. Detention/retention ponds F. Pressure conduit (e.g., single pipe, force mains, Hazen-Williams, Darcy-Weisbach, major and minor losses) G. Energy and/or continuity equation (e.g., Bernoulli) VI. Geometrics A. Basic circular curve elements (e.g., middle ordinate, length, chord, radius) B. Basic vertical curve elements C. Traffic volume (e.g., vehicle mix, flow, and speed) VII. Materials A. Soil classification and boring log interpretation B. Soil properties (e.g., strength, permeability, compressibility, phase relationships) C. Concrete (e.g., nonreinforced, reinforced) D. Structural steel E. Material test methods and specification conformance F. Compaction VIII. Site Development A. Excavation and embankment (e.g., cut and fill) B. Construction site layout and control C. Temporary and permanent soil erosion and sediment control (e.g., construction erosion control and permits, sediment transport, channel/outlet protection) D. Impact of construction on adjacent facilities E. Safety (e.g., construction, roadside, work zone) CIVIL–CONSTRUCTION DEPTH exam Specifications I. Earthwork Construction and Layout A. Excavation and embankment (e.g., cut and fill) B. Borrow pit volumes C. Site layout and control D. Earthwork mass diagrams and haul distance E. Site and subsurface investigations II. Estimating Quantities and Costs A. Quantity take-off methods B. Cost estimating C. Cost analysis for resource selection D. Work measurement and productivity III. Construction Operations and Methods A. Lifting and rigging B. Crane stability C. Dewatering and pumping D. Equipment operations (e.g., selection, production, economics) E. Deep foundation installation IV. Scheduling A. Construction sequencing B. Activity time analysis C. Critical path method (CPM) network analysis D. Resource scheduling and leveling E. Time-cost trade-off V. Material Quality Control and Production A. Material properties and testing (e.g., soils, concrete, asphalt) B. Weld and bolt installation C. Quality control process (QA/QC) D. Concrete proportioning and placement E. Concrete maturity and early strength evaluation VI. Temporary Structures A. Construction loads, codes, and standards B. Formwork C. Falsework and scaffolding D. Shoring and reshoring E. Bracing and anchorage for stability F. Temporary support of excavation VII. Health and Safety A. OSHA regulations and hazard identification/abatement B. Safety management and statistics C. Work zone and public safety | ||||||||

| NCEES - PE Civil Engineering NCEES Engineering Topics | ||||||||

Other NCEES examsNCEES-FE NCEES - FE Civil Engineering 2023NCEES-PE NCEES - PE Civil Engineering NCEES-FE-Electrical-and-Computer NCEES - FE Electrical and Computer 2023 (Actual Questions Test Engine, NO PDF) | ||||||||

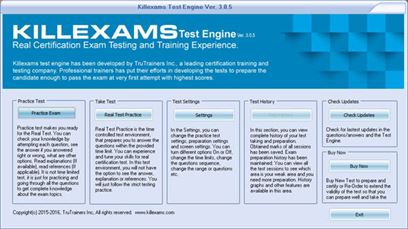

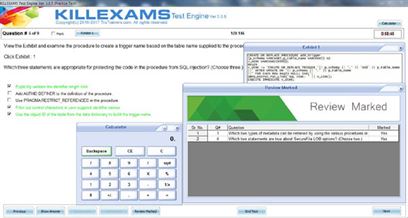

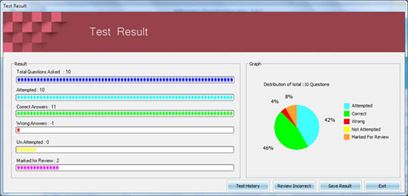

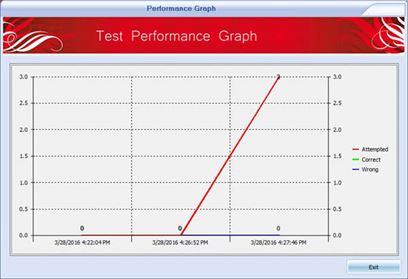

| killexams.com has its experts working continuously to collect, validate and update NCEES-PE dumps. That's why you will not find any other such valid and comprehensive NCEES-PE dumps provider on internet. We claim that, if you memorize all of our NCEES-PE dumps questions and practice with our VCE exam simulator, we certain that you will pass your exam at first attempt. | ||||||||

| NCEES NCEES-PE NCEES - PE Civil Engineering https://killexams.com/pass4sure/exam-detail/NCEES-PE Question: 35 Which of the following assumptions regarding the compression strength of concrete used in reinforced concrete beam design is valid? A. The American Concrete Institute (ACI) recommends that all beams be designed using high strength concrete B. High strength concrete compression strengths range from 3,000 to 7,000 pounds per square inch C. Compression strength of normal concrete ranges from 3,000 to 7,000 pounds per square inch D. None of the above Answer: C The assumption “compression strength of normal concrete ranges from 3,000 to 7,000 pounds per square inch” for the concrete used in reinforced concrete beam design is valid. ACI does not recommend that high strength concrete be used in the design of all beams. The compression strength of high strength concrete ranges from 7,000 - 15,000 pounds per square inch. Question: 36 What is the velocity (in ft/sec) in a rectangular concrete channel with a width of 3 feet (ft), a hydraulic grade line slope of 0.002 ft/ft, a flow depth of 1.5 ft and an assumed Manning's coefficient n = 0.014? A. 0.15 ft/sec B. 1.50 ft/sec C. 3.92 ft/sec D. None of the above Answer: C the velocity in a rectangular channel with the given dimensions is 3.92 ft/sec. Solution: Use Manning's Equation and solve for V V = (K/n) R2/3 Sf1/2 Where: K = conversion coefficient (1.486 for English units, 1.0 for SI) n = 0.014, the Manning coefficient d = depth of flow = 1.5 ft w = width of channel = 3.0 ft Sf= channel slope = 0.002 ft/ft A = Area = d x w = 1.5 ft x 3 ft = 4.5 ft2 P = wetted perimeter = w + 2d = 3 ft + 3 ft = 6 ft R = hydraulic radius = A/P = (4.5 ft2)/ (6 ft) = 0.75 ft V = (1.486/0.014) x (0.75 ft)2/3 x (0.002 ft/ft)1/2 = 3.92 ft/sec Question: 37 The hydraulic radius of a sewer refers to which of the following? A. The diameter B. Channel perimeter C. One-half the diameter D. The ratio of the cross-sectional area of flow to the wetted perimeter Answer: D The hydraulic radius of a sewer refers to the ratio of the cross-sectional area of flow to the wetted perimeter. (The wetted perimeter is the portion of a cross- section’s perimeter that is “wet.”) The equation that describes the hydraulic radius of a channel, Rh, is expressed as follows: Rh = A/P = cross sectional area of flow / wetted perimeter Question: 38 For most proposed land development projects, pre- and post-development watershed drainage patterns are typically evaluated to determine if substantial hydrologic alterations are proposed that will result in which of the following? A. Changes to groundwater recharge B. Changes to water regime within a given resource area C. Increase runoff from the area D. All of the above Answer: D For most proposed land development projects, pre- and post-development watershed drainage patterns are compared to determine if substantial hydrologic alterations will be made to the watershed’s groundwater recharge, water regime, and area runoff. The drainage patterns reviewed include the surface and subsurface paths of water entering, crossing, and leaving the site. Additionally, areas where water is stored within the project site are also evaluated for pre- and post-construction conditions. Question: 39 Euler’s Formula is used to determine which of the following properties related to a simply-supported column? A. Maximum bending moment B. Critical buckling load C. Shear stress D. None of the above Answer: B Euler’s Formula is used to determine the critical buckling load of a simply- supported column. Euler’s Formula is expressed as follows: Fcr = [(E x I)(p2)]/L2 Where: - E = Young’s modulus of the material used to construct the column - I = cross-sectional area moment of inertia - L = column length Question: 40 What is the composite C value for the following drainage area for a 10-year storm recurrence interval?Drainage area: 0.25 acres of residential lots with 40% imperviousness (C = 0.49) 0.25 acres of lawn with 0.95% slope with 0% imperviousness (C = 0.22) 0.10 acres of impervious pavement (C = 0.95) A. 0.20 B. 0.45 C. 0.55 D. Not enough information provided Answer: B The composite C value for the given drainage area for a 10-year storm recurrence interval is 0.45. Solution: Calculate composite C by using the following equation: C = (C1A1 + C2A2 + C3A3) / (A1 + A2 + A3) C = [(0.25 acres x 0.49) + (0.25 acres x 0.22) + (0.10 acres x 0.95)]/ (0.25+0.25+0.10) C = 0.45 For More exams visit https://killexams.com/vendors-exam-list Kill your exam at First Attempt....Guaranteed! | ||||||||

DescriptionThis course provides an introduction to the elements of computer aided design using AutoCAD. Through assignments and projects, students learn various AutoCAD principles, i.e., graphic entities, hatch patterns, layering, and dimensioning, with special emphasis on completing a design project. Two-dimensional drafting and three-dimensional modeling and surface revolution are also discussed. This course is intended for freshmen in civil and environmental engineering majors. Surveying I (Formerly 14.225)DescriptionA presentation of the basic instruments used in survey processes including distance, angle and level measurements. Analysis and adjustment of random errors. Principles of closed and open traverses. Fieldwork practice in instrument use and office-type projects in contour mapping and the application of contoured topography to highway and water-control projects. PrerequisitesMATH 1320 Calc II or Co-Req MATH 1320 Calc II or Pre-Req MATH 1420 Honors Cal II or Co-Req MATH 1420 Honors Calc II or Pre-Req Calc ABC, and Co-Req CIVE 2860 Prob and Stats for Engineers or Pre-Req CIVE 2860 or Pre or Co-req Math.2830. Geomatics (Formerly 14.226)DescriptionPrinciples and practice of route surveys and designs. syllabus include simple and compound circular curves, intersections of straight and curved baselines, vertical alignment principles including parabolic easement curves, earthwork operations and determination of volumes. Includes office-type projects illustrative of the application of surveying information to Civil Engineering projects such as water resources, sanitary sewers and property subdivision. Fieldwork instruction in basic traverse surveys, gathering of topographic information, and the staking-out of buildings and circular curves. PrerequisitesPre-Req: CIVE.2250 Surveying I. Probability and Statistics for Engineers (Formerly 14.286)DescriptionProbability, statistics, reliability and decision with applications in engineering. Probability of events, discrete and continuous random variables, probability density functions and distributions, estimation, regression and correlation techniques, risk and reliability concepts. PrerequisitesPre-Req or Co-Req: MATH 1320 Calculus II. Fluid Mechanics (Formerly 14.301)DescriptionFluid properties, fluid statics, fluid dynamics including continuity, impulse-momentum and energy equations. Pipe flow, turbomachinery, similitude and modeling, laminar and turbulent flow, boundary layer and closed conduct design. PrerequisitesPre-req: MATH 2310 Calculus III, ENGN 2070 Dynamics, MATH 2340 Differential Equations, or MATH.2360 Eng.Differential Equations. Engineering Materials (Formerly 14.310)DescriptionA treatment of the properties of engineering materials that influence the design, construction and maintenance of Civil Engineering works. Included are such materials as ferrous and non-ferrous metals, timber, asphalt, and cementitious materials. Supplemented by laboratory testing of various engineering materials. PrerequisitesPre-Reqs: CHEM 1220 Chemistry II or CHEM 1360 Honors Chemistry II and ENGN 2060 Strength of Materials. Engineering Materials Laboratory (Formerly 14.311)DescriptionExperiments and written reports. Testing and measurement techniques and material standards illustrating behavior of materials, including metals, wood, and Portland cement concrete. PrerequisitesPre-req: ENGN.2060 Strength of Materials. Soil Mechanics (Formerly 14.330)DescriptionDevelopment of the fundamental principles of soil mechanics as utilized in soil and foundation engineering. syllabus include: classification, index properties, strength and stress-strain behavior, effective stress principle, permeability, flow and consolidation. Introduction to basic soil mechanics laboratory practice. PrerequisitesPre and Co-requisites: CIVE.3100 (pre-requisite), CIVE.3330 (co-requisite), and CIVE.3010 or MECH.3810 or CHEN.3030 (co-requisite) Environmental Engineering Laboratory (Formerly 14.332)DescriptionLaboratory experiments to illustrate analysis of environmental samples and experimental techniques, normally used in support of water and wastewater treatment facilities. Course emphasizes data acquisition and analysis, and engineering report writing. PrerequisitesCo-Req: CIVE.3620 Environmental Engineering. Geotechnical Laboratory (Formerly 14.333)DescriptionLaboratory experience that illustrates soil mechanics and fluid flow theory. Experiments are conducted in the soils and hydraulics laboratories. Course emphasizes data acquisition and analysis and writing engineering reports. PrerequisitesCo-Req: 14.330 Soil Mechanics. Transportation Engineering (Formerly 14.340)DescriptionDevelopment of the basic principles pertaining to the movement of people and goods by modern transportation systems. Techno-economic characteristics of the various transportation modes. Aspects of planning, design and operation of land, air and water transportation facilities. Development, structure and function of the U.S. transportation system. PrerequisitesPre-req: MATH.1320 Calculus II, and Pre-req or Co-req: CIVE.2860 Prob & Stats for Engineers, or MATH.2830 Intro to Stats or MATH.3860 Prob & Stats I. Transportation Engineering Laboratory (Formerly 14.341)DescriptionPractice techniques of data collection, analysis and presentation that are commonly used in the planning, design and operation of transportation facilities with primary emphasis on highway systems. Structural Analysis I (Formerly 14.350)DescriptionPrinciples of structural analysis applied to typical civil engineering structures as the initial step in the total design concept. Emphasis on he classical methods of analysis of statically determinate and indeterminate structures. The personal computer as an analytical tool. PrerequisitesPre-Req: ENGN.2060 Strength of Materials. Reinforced Concrete (Formerly 14.352)DescriptionUltimate strength and elastic behavior of reinforced concrete structural members, continuity in building frames, deflections, shear reinforcement, development length and bar cutoffs, columns and footings. PrerequisitesPre-Req: CIVE 3100 Engineering Materials and CIVE 3500 Structural Analysis l. Environmental Engineering (Formerly 14.362)DescriptionPhysical, chemical and biological principles of the treatment of water and wastewater are considered along with their application to treatment systems. The system components of wastewater and water treatment plants are studied to provide a basic design capability. Hazardous waste site remediation is also discussed." PrerequisitesPre-req: CHEM.1220 Chemistry II, and CHEM.1240L Chemistry II Lab, and Co-req: CIVE.3320 Environmental Engineering Lab, and ENGN.2070 Dynamics. Civil Engineering Systems (Formerly 14.372)DescriptionIntroduction to methods of operations research, management science and economic analysis used in the design, planning and managing of engineering systems. Main syllabus covered: systems modeling, optimization concepts, network analysis, mathematical programming, critical path analysis, decision analysis, economic consideration. PrerequisitesPre-Req: MATH 1320 Calculus II and MATH 2310 Calculus III or Co-Req: MATH 2310 Calculus III, pre-req CIVE 2860. Foundation and Soil Engineering (Formerly 14.431)DescriptionThe application of soil mechanics to the design and analysis of foundations and soil structures. syllabus include: soil origin and deposition, subsurface exploration, bearing capacity and settlement analyses, design of shallow foundations, earth pressures, retaining structures, and slope stability. PrerequisitesPre-req: CIVE.3300 Soil Mechanics. Steel Design (Formerly 14.452)DescriptionAn introduction to structural steel design with emphasis on use and interpretation of the AISC Manual and LRFD Specifications. Subjects include design of tension, compression, beams, and beam-column members, plus bolted and welded connections. Other syllabus may include composite beams, plate girders, building connections and plastic analysis and design. PrerequisitesPre-Req: CIVE.3500 Structural Analysis l. Water Resources Engineering (Formerly 14.460)DescriptionThis course is a continuation and extension of Fluid Mechanics, with a focus on engineering applications of hydraulic and hydrologic engineering. This course covers fundamental concepts of open-channel flow, hydraulic structures, design of open channels, surface-water hydrology, and groundwater hydrology. PrerequisitesPre-req: CIVE.3010 Fluid Mechanics, or CHEN.3030 Fluid Mechanics, or MECH.3810 Fluid Mechanics. Introduction to LEED (Formerly 14.466)DescriptionThis course examines the principles of sustainability and how they are applied to engineering and the built environment. Areas covered include energy, water, materials, transportation, and green building principles. Issues of evaluation of sustainability, including life cycle analysis and rating systems, are also discussed. This course fulfills the educational requirements for eligibility to take the LEED (Leadership in Energy and Environmental Design) Green Associate exam. Engineering Economics (Formerly 14.470)DescriptionPresentation of mathematical principles of economic analysis, with emphasis on defining alternatives and predicting consequences of proposed investments. Emphasis is placed on the economic, social and environmental impacts of proposed Civil Engineering projects. The attractiveness of investments is judged by present worth, annual worth, rate of return, and benefit-cost ratio techniques. Sensitivity analysis, depreciation and tax impacts in economic studies are also discussed. Construction Management I (Formerly 14.475)DescriptionDevelopment of management skills and techniques to plan, schedule, supervise, and control construction projects. Project estimating; labor costs and productivity; construction plans, specifications and contracts; labor relations; time, cost and quality control; construction equipment and project decision making and financing. PrerequisitesPre-req or Co-req: CIVE.3720 Civil Engineering Systems. Special syllabus in Civil Engineering (Formerly 14.480)DescriptionContemporary syllabus in selected areas of study within civil engineering. Course content is chosen by the instructor to meet the interests of the students. Special syllabus (Formerly 14.481)DescriptionContemporary syllabus in selected areas of study within civil engineering. Course content is chosen by the instructor to meet the interests of the students. Spec Topics: Civil Engineering (Formerly 14.483)DescriptionContemporary syllabus in selected areas of study within civil engineering. Course content is chosen by the instructor to meet the interests of the students. Capstone Design (Formerly 14.485)DescriptionIntroduction to the essentials of engineering design and a forum for practicing the design process. Integrates many elements of the curriculum through a comprehensive design project to professional standards. Projects includes the use of open-ended problems, feasibility analysis, complete design process, consideration of alternative solutions, and cost estimation. Students practice team effort, development of a system perspective, communication skills, reporting, and presentations. PrerequisitesPre-Req: Senior Status. Industrial Experience I (Formerly 14.491)DescriptionThe new Cooperative Education program for undergraduates combines academic studies with work experience in appropriate positions in the public or private sectors. It permits students to participate in the flexible schedule of study and work that is related to their academic fields of study and to receive academic credit for the work experience. Requires 500 hours of cooperative education engineering experiences, on a full-time or part-time basis, during any academic semester or summer. All co-op work must be pre-approved by the Co-op Coordinator. (Effective with Class of 2001-02, students in CEE are able to earn three credits after the successful completion of both Industrial Experience I and II). "Variable credit course, student chooses appropriate amount of credits when registering." PrerequisitesJunior level and 2.0 GPA or higher. Industrial Experience II (Formerly 14.492)DescriptionThe new Cooperative Education program for undergraduates combines academic studies with work experience in appropriate positions in the public or private sectors. It permits students to participate in the flexible schedule of study and work that is related to their academic fields of study and to receive academic credit for the work experience. Requires 500 hours of cooperative education engineering experiences, on a full-time or part-time basis, during any academic semester or summer. All co-op work must be pre-approved by the Co-op Coordinator. (Effective with Class of 2001-02, students in CEE are able to earn three credits after the successful completion of both Industrial Experience I and II). PrerequisitesPre-req or Co-req: CIVE.4910 Industrial Experience I, and Junior level and 2.0 GPA or higher. Industrial Experience III (Formerly 14.493)DescriptionThere is currently no description available for this course. Environmental Engineering ChemistryDescriptionOverview of fundamental chemistry related to the source, fate and reactivity of compounds in the atmosphere, hydrosphere, and lithosphere. syllabus include reaction kinetics, chemical equilibrium, redox reactions, chemical thermodynamics, carbonate systems, environmental fate of chemicals in natural and polluted environments, anthropogenic and natural pollution. PrerequisitesPre-Req: CHEM.1220 Chemistry II OR equivalent course. Fluid Mechanics LaboratoryDescriptionLaboratory and field experiments on fluid mechanics including measurement of fluid properties, analysis of fluid flow patterns and fluid flow in closed conduits, and flow measurements. Course emphasizes data acquisition and analysis, and report writing. PrerequisitesPre-req: MATH.2310 Calculus III, and ENGN.2070 Dynamics, and MATH.2360/2340 Differential Equations, and Co-req: CIVE.3010 Fluid Mechanics. Material Science for Environmental EngineeringDescriptionA treatment of the properties of engineering materials that influence the design, construction and maintenance of Civil Engineering works. Included are such materials as ferrous and non-ferrous metals. PrerequisitesPre-req: CHEM.1220 Chemistry II, or CHEM.1360 Honors Chemistry II, and ENGN.2070 Dynamics. Environmental Engineering IIDescriptionThis course emphasizes the ecology and physical-chemical processes used in water and wastewater treatment. syllabus covered include Streeter-Phelps model, coagulation, flocculation, water softening, precipitation, filtration, activated carbon adsorption, and disinfection. PrerequisitesPre-req: CIVE.3620 Environmental Engineering I, and ENVE.2010 Environmental Engineering Chemistry. Energy and the Sustainable EnvironmentDescriptionThermodynamic laws, energy balance, conservation of energy, heat transfer, energy conversion and efficiency, ideal and non-ideal gas and gas mixtures, design and evaluation of renewable energy systems. PrerequisitesPre-req: PHYS.1410 Physics I, and CHEM.1220 Chemistry II, and MATH.1320 Calculus II. Groundwater Hydrogeology and RemediationDescriptionGroundwater flow and aquifer behavior in response to pumping will be addressed. Analysis of contaminant transport and the formation of multi-dimensional contaminant plume formation will be conducted. Physical, chemical and biological based technologies for contaminated aquifer remediation are covered. PrerequisitesPre-req: BIOL.2100 Biology for Engineers, and CIVE.3010 Fluid Mechanics, and CIVE.3620 Environmental Engineering I. Biological Processes in Environmental EngineeringDescriptionThis course focuses on the fundamental aspects of biological processes that are commonly used in water and wastewater treatment. syllabus covered include: the mechanisms and kinetics of biological reactions, mass balances of biological reactors, biological reactor design and diagnosis, and aeration and gas transfer. PrerequisitesPre-req: CIVE.3620 Environmental Engineering I, and BIOL.2100 Biology for Engineers. Chemical Fate and Transport in the EnvironmentDescriptionThe properties of organic chemicals and equilibrium chemistry controlling the distribution of these chemicals between air, water and soil will be studied. Transport processes and the lifetime of chemicals in the environment will be investigated. Risk assessment for the exposure to chemical contaminants will be addressed. PrerequisitesPre-req: ENVE.3650 Groundwater Hydrogeology and Remediation. Air QualityDescriptionReview of gaseous pollutants, their chemistry and properties. Emissions of air pollutants (mass balances) and atmospheric sciences related to air pollution. Gas and particulate handling and treatment technologies are addressed. PrerequisitesPre-req:CIVE.3010 Fluid Mechanics, and CIVE.3620 Environmental Engineering I. Environmental Eng. Ethics and Professional PracticeDescriptionThis course introduces students to the American Society of Civil Engineers (ASCE) code of ethics and standards of practice for environmental professionals. syllabus include codes of ethics, agreements and contracts, ethical and legal considerations, professional liability, public protection issues, environmental regulations, and environmental sustainability considerations. It prepares students to think critically while working with complex environmental issues. PrerequisitesPre-req: CIVE.3620 Environmental Engineering I. Solid Waste Engineering and ManagementDescriptionGeneration, storage, collection, transfer and transport, processing and disposal of municipal solid wastes; treatment and disposal of water and wastewater treatment sludge; landfill design; alternative waste management and disposal strategies. PrerequisitesPre-req: ENVE.3630 Environmental Engineering II, and ENVE,3660 Biological Processes in Environmental Engineering, and CIVE.3720 Civil Engineering Systems. Capstone DesignDescriptionIntroduction to the essentials of engineering design and a forum for practicing the design process. Integrates many elements of the curriculum through a comprehensive design project to professional standards. Project includes the use of open-ended design problems, feasibility and impact analysis, complete design process, consideration of alternative solutions, and cost estimation and scheduling. Students practice team effort, development of a system perspective, communication skills, reporting, and presentations. The course is fast paced and covers new design elements in each module. PrerequisitesPre-Req: Senior Status. As a licensed Professional Engineer, or PE, you can expect many more benefits when compared to other engineers; most employers offer higher salaries and greater opportunities for advancement to PE's. Only PE's can consult in private practice, and seal company documents to be sent to the government. PEs also have more credibility as expert witnesses in court than most engineers. Steps in obtaining a PE license:

During your senior year you should take the Fundamentals of Engineering (FE) exam, which is required prior to sitting for the Professional Engineers (PE) Exam. Some requirements vary by state. Engineering courses have been offered at Hope College since 1979. Initial offerings were instituted by the Department of Physics in response to academic interests of students who were majoring in physics but whose career goals were in engineering. At that time, two faculty members, with interests and training in engineering, began offering a limited number of courses in basic mechanical and electrical engineering topics. During the decade of the 1980s, these courses included Solid Mechanics, Electronics, Thermodynamics, Fluid Mechanics, Material Science and Vibrations. This curriculum was designed and intended to prepare students for graduate study in engineering. Another option for engineering students was the Hope College Engineering 3-2 Program, in which students combined three years of study at Hope College with two years at a traditional engineering school. Upon successful completion of this program, students received a Bachelor of Science degree from Hope College and a Bachelor of Engineering degree from the engineering school. During the mid to late 1980s, the Department of Physics recognized that the current engineering offerings were not providing enough depth of coverage to ensure student success in graduate engineering studies. For this reason, a Bachelor of Science degree with a major in Engineering Physics was established in 1989. The objective of this degree program was to Improve the preparation of physics students for continuing on in engineering graduate school. In order to meet the requirements of this new major, the curriculum was modified to offer engineering courses on an alternate year basis. This arrangement allowed efficient use of the existing engineering faculty to provide students with a course pattern which more closely resembled that of a traditional four-year engineering school. As a result of these improvements to the engineering curriculum, the popularity of the 3-2 Program diminished as a majority of engineering students decided to remain at Hope College for four years to pursue a major in Engineering Physics. Most of these students continued their studies in engineering graduate school, although a fair number of students began pursuing employment in industry directly from Hope College. In 1994, the engineering faculty increased to four members through the addition of two new hires. This growth was partially supported by a grant from the Fund for the Improvement of Post-Secondary Education (FIPSE, administered by the Department of Education), which was granted to the college to develop a model for engineering programs at liberal arts colleges. The educational objectives of this expansion were to implement a capstone engineering design experience, provide core engineering classes on an every-year basis, and to increase the number of engineering syllabus courses offered. These objectives were successfully achieved with the implementation of several changes, including:

From 1994 to 1997, as part of the FIPSE-sponsored study of the Engineering Program, a number of external reviewers from both small and large engineering colleges served as external advisors to the Engineering Program. Reviewers completed campus visits in order to assess the Engineering Program. Based partly on the largely positive reviews of the Engineering Program, the department requested permission from the administration of Hope College to pursue an accredited engineering degree. The motivation for pursuing accreditation was to further Improve the quality of engineering education at Hope College by formally implementing a system of continuous improvement via both internal and external review and assessment. The Administration of Hope College approved the pursuit of an accredited engineering program in 1997, and the department established a new degree designation: the Bachelor of Science with a Major in Engineering. This new engineering major was designed and intended to fulfill the degree requirements as specified by the ABET 2000 criteria. It was decided to retain the less rigorous engineering degree (which is not accredited and for which no accreditation is sought) the Bachelor of Science with a major in Engineering Science. This degree provides engineering education for students who have other interests, such as a second major in another degree program, that preclude their ability to complete the engineering major requirements within their time at Hope College. Also in 1997, a fifth engineering faculty member was hired to continue building ties with local industry, to increase offerings in engineering syllabus courses (heat transfer and a thermofluids laboratory) and to provide necessary support for implementing assessment and outcomes instruments as required by ABET 2000 criteria. In 1998, the Hope College Curriculum Committee officially approved the new engineering major, and the Department of Physics changed its name to the Department of Physics and Engineering. Developing engineering skills today for a more sustainable tomorrow. ESF Home > Environmental Resources Engineering

Our departmental mission is to engage in teaching, research, and service to advance environmental resources engineering practices and meet the needs of the world. Our faculty strengths are in ecological engineering, geospatial engineering, water resources engineering, and the broader field of environmental resources engineering. Teaching includes innovative class, lab, and field exercises in foundational and advanced engineering topics, where our flexible curriculum allows students to focus on traditional or novel engineering practices. Students receive a well-balanced education, including courses that consider the social, economic, and environmental impacts of engineering practice, fundamental engineering and environmental engineering courses, and specialized courses that capture the breadth of their field of study. The ERE department is internationally recognized for coupling research and service, and many of our courses address community needs. We provide unparalleled mentoring to train students in engineering science and design so they can join our alumni as leaders in professional practice and research. Explore ERE's Mission Statement, Educational Objectives, and Student Outcomes Undergraduate Degree ProgramEnvironmental Resources EngineeringPreparing qualified engineers to operate with professional competence. Learn More Student Clubs and OrganizationsERE ClubThis club familiarizes members with current developments and events in the field of environmental resource engineering. There is an emphasis on professional development and enhancing student-student and student-faculty relationships among those in the ERE curriculum. Engineering for a Sustainable SocietyEngineering for a Sustainable Society (ESS) is a student-initiated university chapter of the national organization. This organization is devoted to implementing low-tech, high-impact, engineering projects as a means of improving the quality of life and environment all over the world. Engineers Without BordersThe ERE Department maintains a student chapter with the national Engineers without Borders organization, organized by the ESS officers. The ESF EWB club has been coordinating international projects since 2003 and is active with the local professional EWB chapter. NY Water Environment AssociationThe New York Water Environment Association Student Chapter engages students in the water resources profession, with an emphasis on water supply and wastewater systems. The student chapter participates in service activities, professional meetings, seminars and conferences to promote sustainable water quality management in order to create an environmentally sound future. We have to admire a YouTube channel with the name [Less Boring Lectures]. After all, he isn’t promising they won’t be boring, just less boring. Actually though, we found quite a few of the videos pretty interesting and not boring at all. The channel features videos about mechanical engineering and related subjects like statics and math. While your typical electronics project doesn’t always need that kind of knowledge, some of them do and the mental exercise is good for you regardless. A case in point: spend seven minutes and learn about 2D and 3D vectors in two short videos (see below). Or spend 11 minutes and do the whole vector video in one gulp. These reminded us of Kahn Academy videos, although the syllabus are pretty hardcore. For example, if you want to know about axial loading, shear strain, or free body diagrams, this is a good place to look. There are a lot of things we tend to just guess at when doing projects, like what kind of bolts to use to hold things together. Usually, we overdesign and use our experience, but if you really want to optimize what you are doing or you need to be absolutely sure, there are syllabus on bolt tension and failure theories. There are also good videos about gears and bearings and other traditional mechanical engineering topics. Will you get as much out of these videos as you would taking some engineering classes at the local university? Maybe not. But you might remember about the same amount of things in six months. Funny how that works. We find we’ve been much more interested in mechanics since we’ve been 3D printing. Some of that is because we want to design better models, but sometimes we are more interested in the machine itself. FE ExamPrepare for the Fundamentals of Engineering (FE) exam, taken in your fourth year. The FE exam is generally the first step in the process to becoming a professional licensed engineer (PE). The FE exam is administered by NCEES, the National Council of Examiners for Engineering and Surveying. It is designed for latest graduates and students who are close to finishing an undergraduate engineering degree from an EAC/ABET-accredited program. The FE exam is a computer-based exam administered year-round at NCEES-approved Pearson VUE test centers. Review Session VideosMichigan Tech offers lecture review sessions on civil and environmental engineering topics. Hydrogeology/Water Resources Review NotesNRCS (SCS) Rainfall-RunoffEquations

Variables

Rational FormulaEquationsVariables

Darcy’s LawEquations

Variables

Definitions

Well DrawdownIllustration

Dupuit’s FormulaEquations

Variables

Illustration

Equations

Variables

Groundwater Flow

Equations

Variables

Notes

Intrinsic PermeabilityMost important properties affecting the magnitude of intrinsic permeability include:

Intrinsic permeability is proportional to the square of the grain diameter. A table is given for the median size of fine, medium, and course sand to show the difference by orders of magnitude in the intrinsic permeability. Seepage VelocityDarcy velocity or specific discharge (ie, flow rate per total area) is used for water supply (volume). Average pore or seepage velocity, which reflects the average velocity of groundwater in pore spaces, is of interest for contaminant transport and geotechnical problems. AquifersAquifers are geological formations that are saturated with water. Equations

Variables

Notes

Well Hydraulics (Ideal)Equations

Variables

Aquifer BehaviorUnconfined aquifers have a “free” water surface or groundwater table, which is at atmospheric pressure and below which the pressures are normally hydrostatic. Confined aquifers are overpressured, and the potentiometric surface is above the top of the aquifer. The top of the aquifer is a confining unit (aquitard or aquiclude). Illustrations

ConfinedSolutions to the groundwater flow equation for a single pumping well in a fully confined aquifer: Equationsdrawdown, a potentiometric surface from static (unpumped, initial) level Assumptions

Solutions

Example

Special Condition: Steady State (Equilibrium)In addition to the assumptions for the Theis solution (ie, ideal aquifer and pumping conditions), assume that the potentiometric surface has stabilized. In this case, the Theim solution applies, which comes from integrating Darcy’s Law for axisymmetric flow to the pumping well. UnconfinedApplication of the Thiem solution to an unconfined aquifer: Equations

Special case for a pumping well. Example of Steady State Well HydraulicsCalculate the specific capacity for confined and unconfined. Soil and Groundwater RemediationContaminant Phases